It is no secret that carbon levels in the atmosphere have been on the rise and are one of the primary concerns when it comes to global warming and environmental sustainability. One of the main sources of CO2 emissions and contributors to large carbon footprints are internal combustion engine vehicles (ICEVs); the other is fossil fuel-based electricity generation.

In the next two decades, electric vehicles (EVs) are set to dominate the auto industry, yet they face one major hurdle: battery storage. This is where lithium comes in. Lithium-ion batteries power our laptops and cell phones now, but they will also become the key driving force for electric vehicles because of their light weight, and high energy density. An impactful and game-changing energy material, lithium is set to define the EV industry due to its unique energy-storing properties and its relatively low environmental impact. Inherently less polluting than a traditional ICEV, electric vehicles and their lithium-ion batteries will be part of a major transition away from fossil-fuel vehicles.

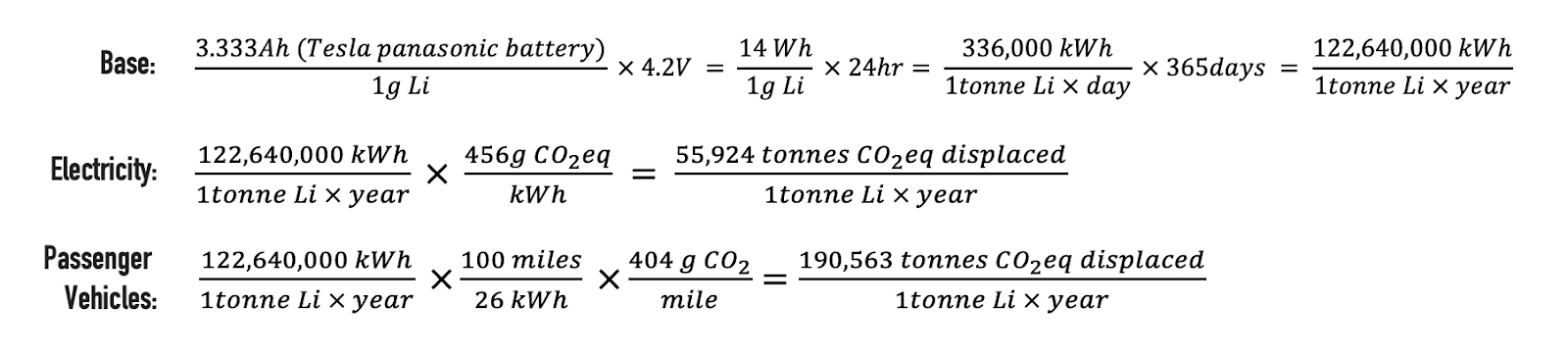

EnergyX has done the calculations:

According to the United States Environmental Protection Agency, “the average passenger vehicle emits about 404 grams of CO2 per mile” and “about 4.6 metric tons of carbon dioxide per year”. For every single ton of lithium used in EV batteries, it would displace 190,000 tons of CO2 per annum that would otherwise be emitted by ICEVs. Every ton of lithium utilized as storage for renewable solar or wind energy would save 56,000 tons of CO2 that could be produced by fossil-fuel power plants.

If an electric vehicle was charged using electricity generated by conventional coal or natural gas sources, as opposed to renewable energy sources, one extra ton of lithium utilized in the energy ecosystem would still displace 134,000 tons of CO2 on an annual basis. On top of this, if the EV was charged by fossil-fuel generated power for its entire lifetime, that upstream emission would still produce significantly less carbon emissions that an ICEV, not including the calculations of gasoline production.

Right now, current methods of extracting lithium from brine pools and reservoirs include natural evaporation and techniques requiring extensive processing. These processes can take months and produce copious amounts of waste while posting an actual lithium recovery rate of 30%. EnergyX’s GET-Lit™ technology not only increases lithium recovery rates while keeping costs and time low, but also decreases the energy needed to extract it. Lithium and lithium-ion batteries will play a major role in the rapid growth of the clean energy industry. Furthermore, if commercialized, energy systems like GET-Lit™ will not just revolutionize the energy storage sector, but help define a new chapter in global sustainability.