Can AI Reinvent Cell Formation and Quality Assurance?

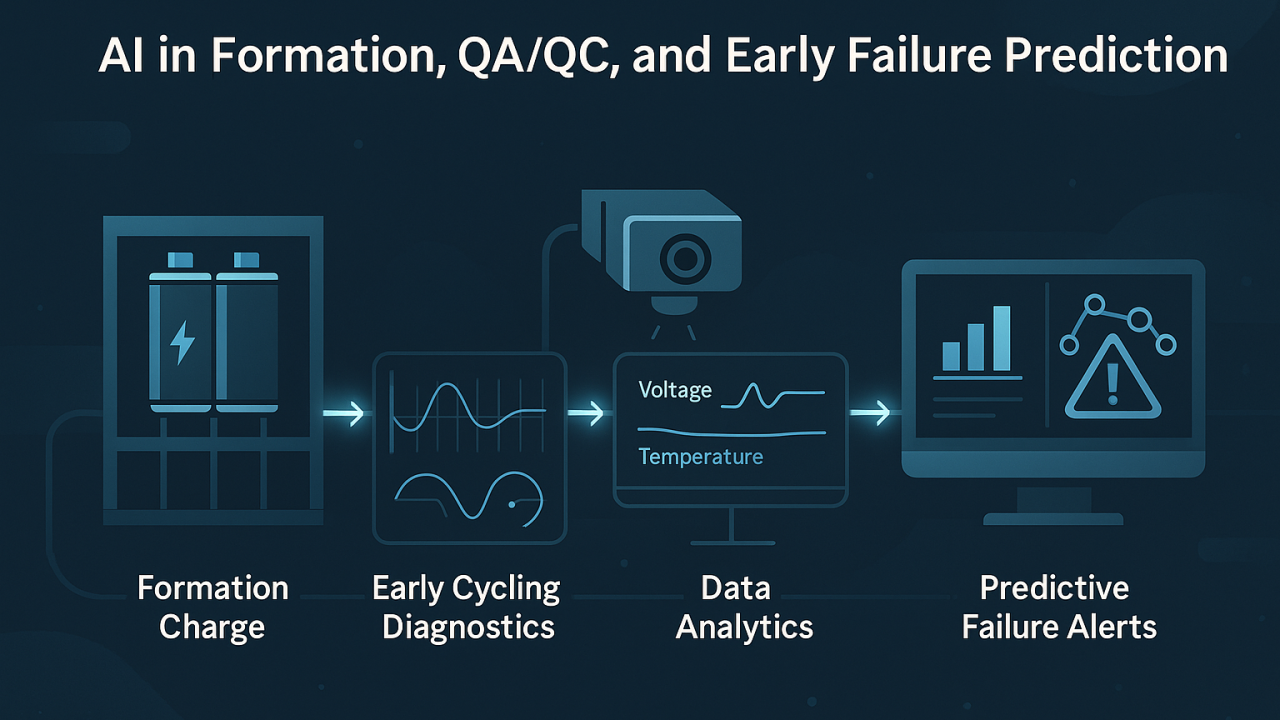

Formation is often described as the heart of lithium‑ion battery manufacturing. It is the first time a cell is charged, the moment when its interphase begins to form, and the step where latent defects tend to reveal themselves. It is also one of the most expensive and time‑consuming parts of the entire production process. The question today is simple: can AI make formation, quality assurance, and early failure prediction faster, smarter, and more reliable?

This article explores what’s working, what isn’t, what’s next, and how AI is transforming formation protocol design, formation diagnostics, inline inspection, predictive QA, and warranty‑relevant failure analysis.

What’s Working

Before diving into specific real world examples, it is useful to look at the high level areas where AI is already making measurable progress in formation and quality assurance. Several factories have moved these capabilities from pilot lines into full production, offering a clear picture of what is achievable today.

1. Data‑driven formation optimization. Leading manufacturers are now training AI models on gigabytes of formation cycling curves, impedance data, voltage profiles, and pressure or expansion measurements. These models identify the most stable SEI formation pathways for different chemistries and optimal parameters for cycling/performance. Several companies have reduced formation time by ten to twenty percent through adaptive current and temperature profiles.

2. Inline inspection powered by computer vision. Although briefly touched on in Part 6, it is worth mentioning again how AI is aiding in cell manufacturing in-line inspection owing to the direct consequences on formation and ensuing cell performance.High‑resolution cameras and AI classifiers are used to detect electrode misalignment, tab defects, weld inconsistencies, and electrolyte wetting patterns.

3. Predictive QA for grading and sorting. AI models combine early cycling results with impedance and thermal data to predict ultimate capacity retention, calendar life, and cycle life. This enables tighter binning and more accurate separation between top‑tier and mid‑tier cells.

Real‑world examples. CATL has applied adaptive formation analysis across several production lines to shorten formation windows. Tesla integrates machine‑learning classifiers within its pack‑level end‑of‑line testing. Panasonic and LG Energy Solution use inline vision systems for weld quality inspection on cylindrical and pouch lines. Voltaiq provides advanced analytics that examine early cycling, impedance, and thermal signatures to detect quality issues within hours rather than weeks, enabling faster identification of defective cells and tighter feedback loops across post‑manufacture QA.

What’s Missing

Even with meaningful progress across formation and QA, several structural and technical barriers continue to limit the impact of AI. Understanding these gaps helps clarify why some tools scale smoothly while others stall at the pilot or demonstration stage.

1. Lack of standardized data structures. Formation and QA data are still fragmented across equipment suppliers. Different cyclers, welders, and leak testers generate incompatible formats, slowing down factory‑wide AI adoption.

2. Limited real‑time visibility into SEI formation. Most SEI insights come from cycling data rather than direct physical measurement. Without real‑time interphase diagnostics, AI models remain constrained by indirect indicators.

3. Insufficient integration between process stages. Electrode manufacturing, cell assembly, formation, and testing operate in silos. AI models cannot reach full potential without unified end‑to‑end datasets.

4. Warranty data remains a black box. Manufacturers rarely share field failure data openly. This limits the training of models that could connect early‑life signals with long‑term warranty risk.

What’s Next

The next wave of innovation will link manufacturing, formation, diagnostics, and field performance into a continuous learning loop. This will push formation from a static sequence into a dynamic, adaptive step that improves reliability and yield.

1. Self-optimizing formation protocols. Factories will move toward closed-loop formation systems that adjust current, temperature, and voltage settings in real time based on each cell’s early response. These adaptive controls will shorten formation time while improving consistency.

2. Physics-informed AI for SEI prediction. Hybrid models that combine electrochemical principles with machine learning will enable more accurate predictions of SEI structure, gas evolution, and long-term stability. These methods can also support advanced chemistries where interphase behavior is critical, including rechargeable lithium metal batteries.

3. Full digital threads connecting materials to warranty outcomes. AI platforms will connect the entire lifecycle of a cell, from mineral feedstocks and electrode properties to formation signatures and real-world performance. This will allow manufacturers to tune formation protocols to compensate for minor upstream defects and will make it possible to trace field failures back to specific stages in the supply chain. These insights will accelerate learning across the entire system and may uncover new scientific understanding of degradation pathways and failure modes.

4. Earlier detection of latent defects. By integrating mechanical, thermal, acoustic, electrical, and vision data, AI will detect cells that are likely to fail long before they reach end users. This will reduce warranty exposure and support higher levels of safety and reliability.

By: Dr. Nicholas Grundish