Project Black Giant™

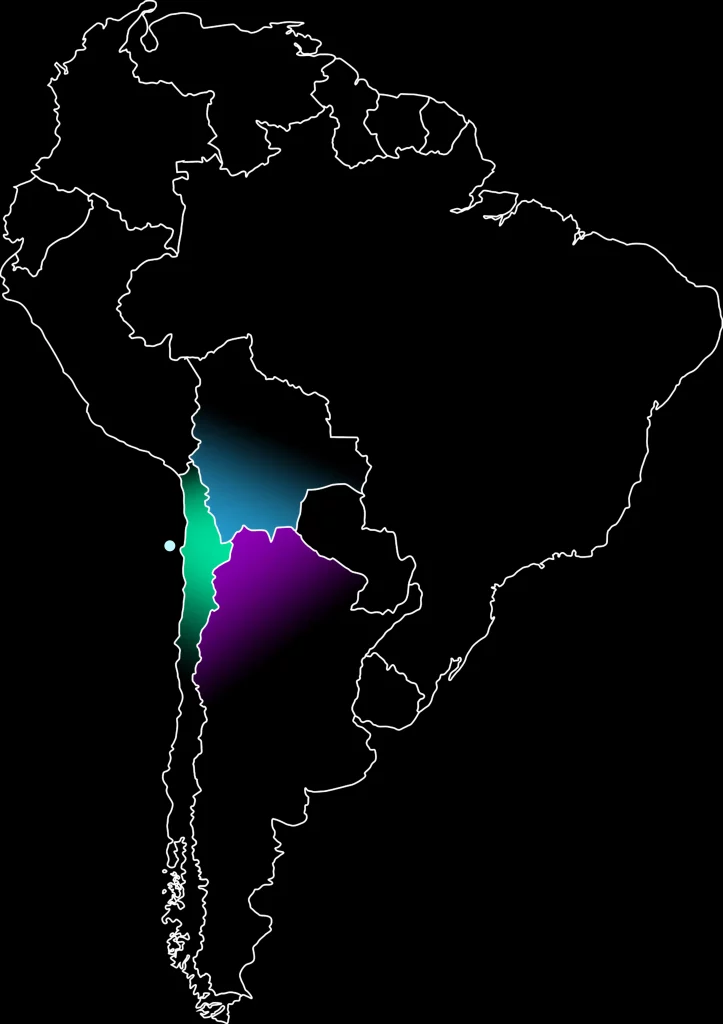

ANTOFAGASTA, CHILE

Quick

Facts

Project Size

Battery Grade Lithium

Lithium Concentrations

Quick

Facts

Project Size

52,500 tpa LCE

Battery Grade Lithium

99.9%

Lithium Concentrations

300-1,050 mg/L

PROJECT OVERVIEW

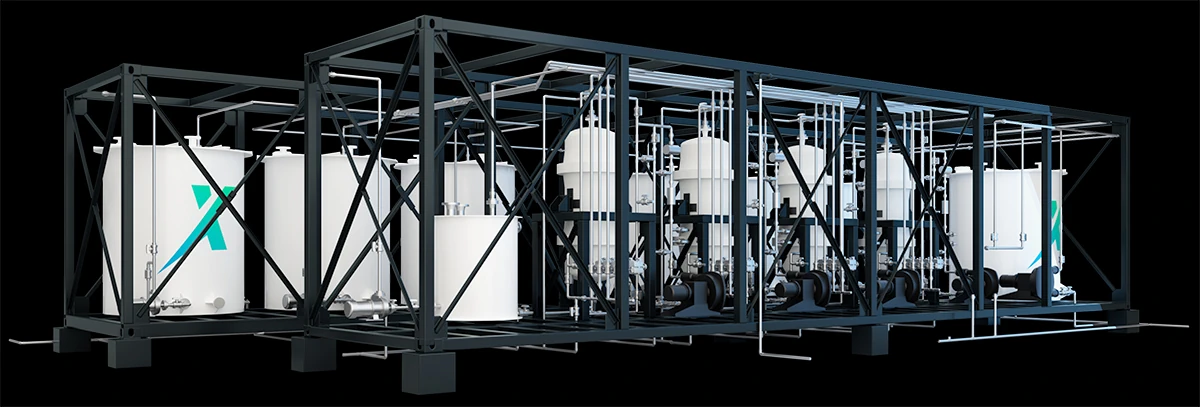

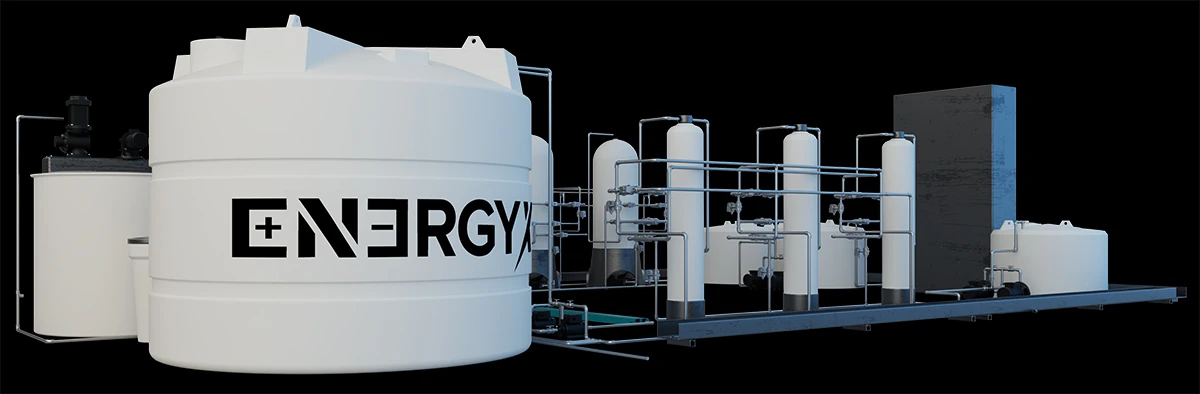

In 2023, EnergyX made a significant leap by acquiring a ~100,000-acre lithium resource in Chile, where we plan to develop one of the world’s first commercial Direct Lithium Extraction (DLE) facilities, along with a refinery near the port. This project, known as Project Black Giant™, marks the company’s first lithium acquisition. Here’s a closer look at the exciting details of this groundbreaking venture:

- 100,000+ acres of high-quality lithium mining concessions.

- Total potential ranges from 4.5 to 9.8 million metric tons of lithium

- Well samples show lithium concentrations topping 1,150 mg/L

- With our technology, we estimate Project Black Giant will be able to produce 52,500 tpa LCE of lithium per year.

| Resource Location & Size | 100,000+ Acres in Antofagasta Region |

| Initial Annual Production | 7,500 tpa LCE (Phase I), 52,500 tpa LCE (Phase I & II) |

| Production | 99.9% Battery Grade Li2CO3 |

PROJECT PROGRESS

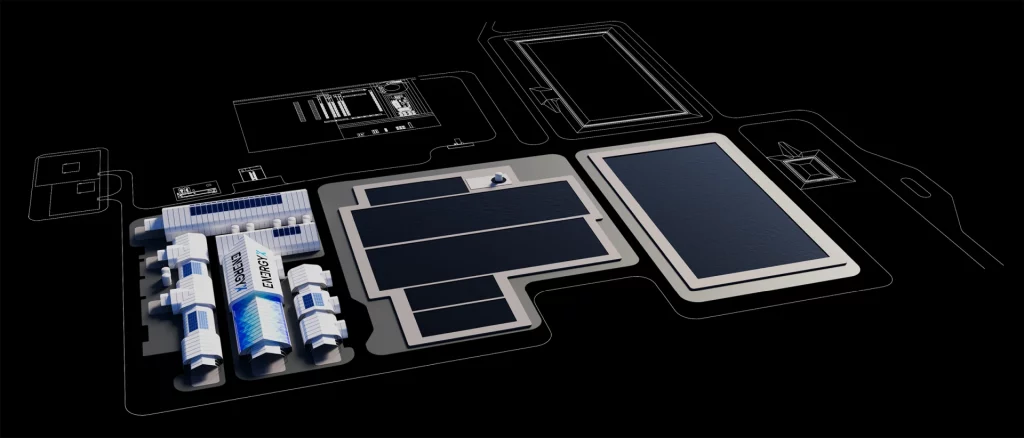

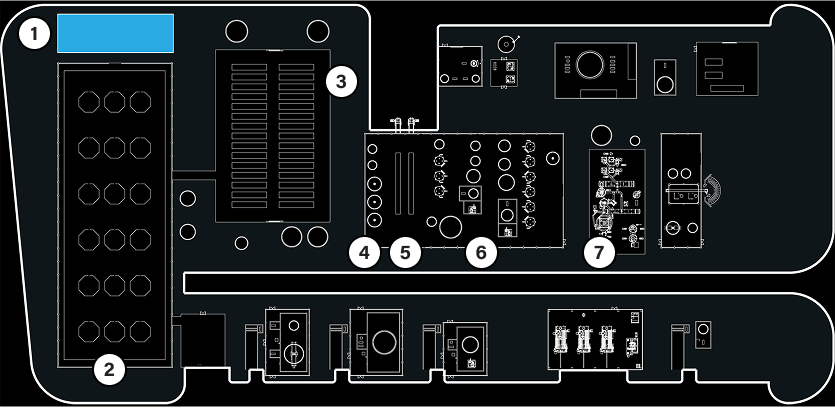

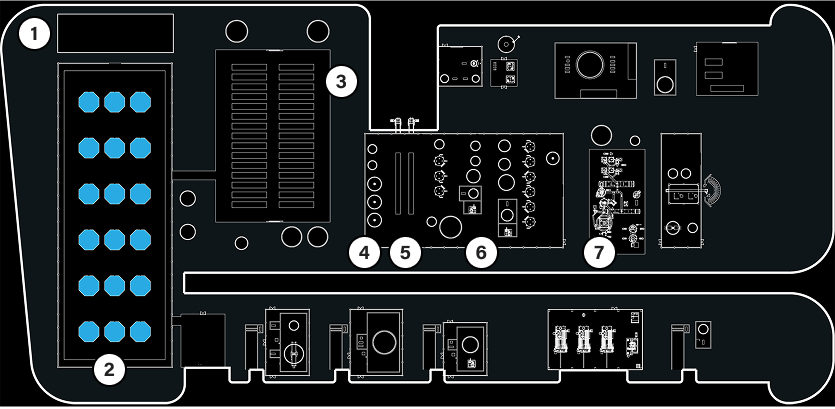

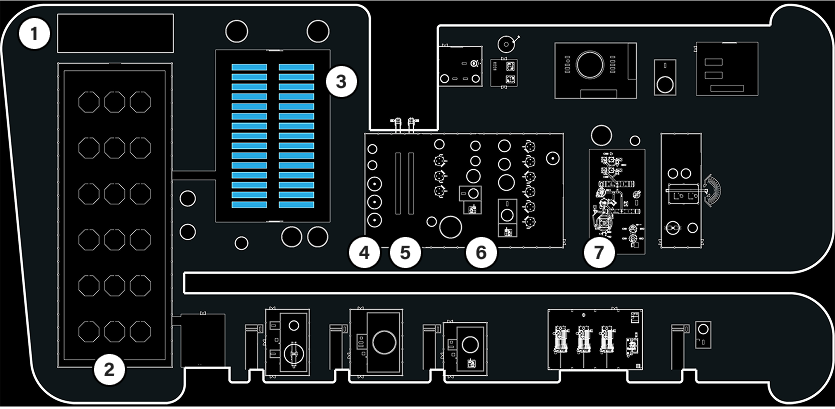

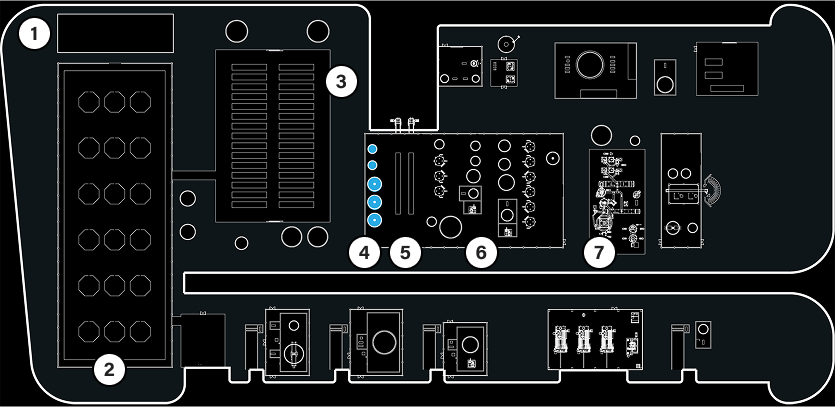

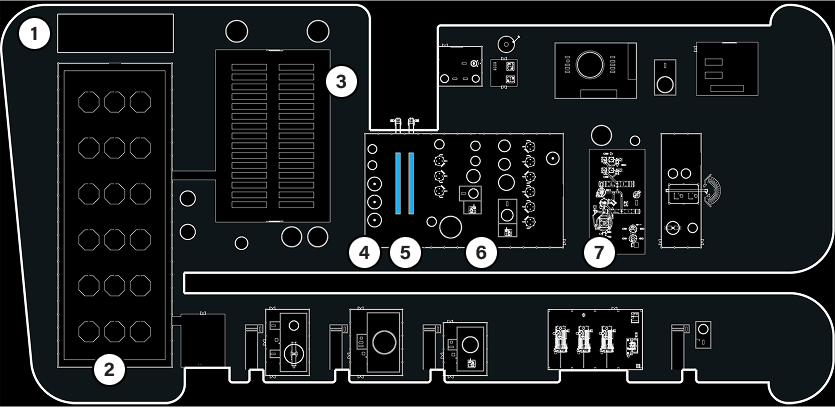

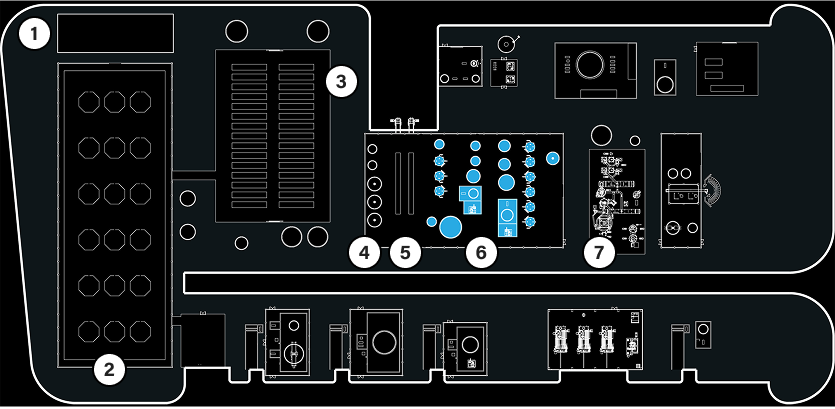

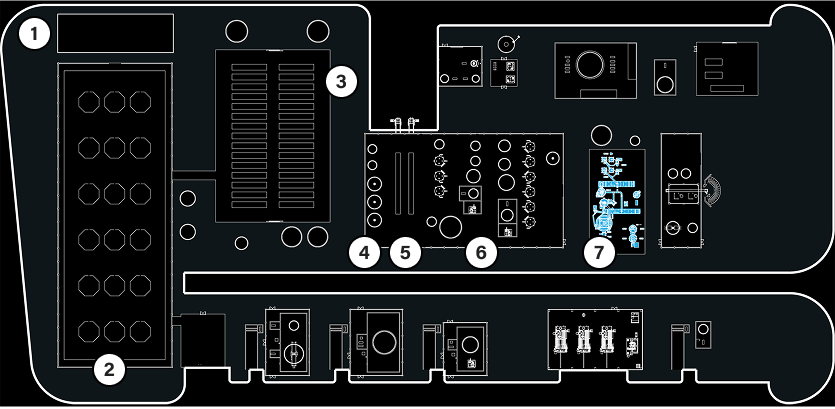

At Project Black Giant™, EnergyX is making incredible strides. The pilot plant in Antofagasta is producing battery-grade lithium, a critical milestone that demonstrates our technology’s commercial viability. We’ve fully built out a 54,000-square-foot facility—including laboratories, offices, a cantina, and pilot/demo facilities—to process Black Giant brine.

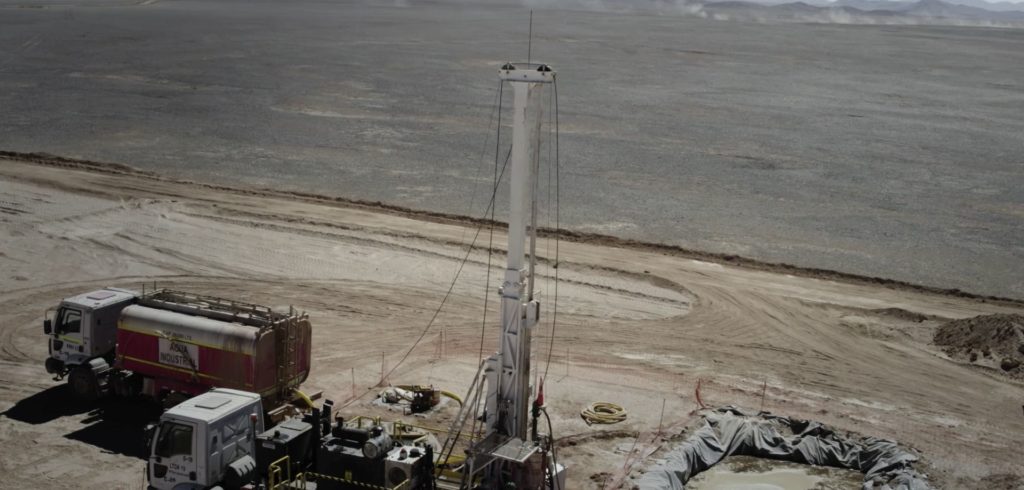

The exploration team has grown and continues around the clock operations. They have successfully completed the 14-hole Phase 1 Drilling Program, and are now underway with Phase 2 Drilling.

PROJECT FEASABILITY STUDY

In partnership with:

Study approach

EnergyX has successfully finalized the Pre-Feasibility Study (PFS) for its Chilean lithium resource, Project Black Giant™, in partnership with Montgomery & Associates, Geobiota, and Worley. The study confirms the economic viability of the project, marking a significant step toward commercial-scale lithium production, while also highlighting EnergyX’s industry-leading low CapEx and OpEx. Additionally, the full resource report for the Project Black Giant resource underscores the project’s long-term potential.

The PFS study validates the feasibility of the project, demonstrating that large-scale lithium extraction and production are both economically and technically viable. Collaboration with Worley enhances the overall project development strategy, ensuring efficiency and sustainability.

As EnergyX advances toward full-scale commercialization, these results further solidify the company’s strategic leadership in the lithium industry. By demonstrating exceptional extraction efficiency and economic viability, EnergyX is strengthening its competitive edge while ensuring long-term sustainability, resource security, and the scalability necessary to meet the surging global demand for lithium.

ECONOMIC IMPACT

LOWEST

CAPEX & OPEX

Industry-leading efficiency

Unmatched Cost Efficiency Across the Industry.

100k+

MINERAL ACRES

RICH LITHIUM RESOURCES

Spanning 100,000+ acres, with lithium concentrations ranging from 300 to 1,150 mg/L.

3RD

PARTY VERIFIED

TRUSTED DATA INTEGRITY

Independent validation of resource estimates and engineering ensures reliable and accurate results.

52K

TONNES/YEAR

TIER 1 CAPACITY

Output targets place Project Black Giant™ among industry leaders for production capacity.

Environmental Sustainability

Project Black Giant™ isn’t just a technological breakthrough — it’s a commitment to the planet and the people who call it home.

We’re redefining what responsible innovation looks like:

ZERO WATER EXTRACTION

We respect and protect the land. Our process uses no water from or around the salar — a critical promise to the local Indigenous community and the delicate ecosystems they’ve stewarded for generations.

POWERED BY THE SUN

Nearly 80% of our operations run on solar energy, dramatically reducing our carbon footprint and proving that clean energy can power industry at scale.

We believe the future is sustainable — and we’re building it, one bold step at a time.

Our journey

Project Black Giant™ marks a major step forward for EnergyX, with key milestones including groundbreaking technology deployment, strategic partnerships, and accelerated progress toward scalable lithium production.

2023

Chile Lithium

Resource Acquisition

EnergyX purchases its first wholly owned lithium resource (Project Black Giant) in IRA-compliant Chile. 100,000+ acres in Salar de Punta Negra.

Drilling Commences

14-hole Phase 1 Drilling Program is complete, and are now underway with Phase 2 Drilling.

Q2 2024

Q3 2024

$690m Debt LOI

EnergyX signs LOI for $690 million project finance with US Export Import Bank (EXIM) in July 2024 to supply the debt for Project Black Giant in Chile

54,000-square-foot facility

Crews from the U.S.traveling regularly to support operations. EnergyX has fully built out a 54,000-square-foot facility—including laboratories, offices, a cantina, and pilot/demo facilities—to process Black Giant brine

Q4 2024

Q1 2025

Worley Completes PFS

EnergyX brings on Worley (Tier 1 EPC) to complete design and engineering PFS for both US and Chile projects

The world is watching Project Black Giant™

We’ve been featured by some of the most influential voices in the media worldwide. Explore some of the top stories below: